Environmental health, human health and economic health are inextricable. For the first time in 50 years, we can’t congregate to honor Mother Earth. But we can — and must — collaborate.

[panini-row layout=”row-full” ] [panini-column ] [paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”] [content name=”content” label=”Paragraph Content”] This newly expanded and now quarterly Sustainability Snapshot will communicate relevant sustainability news and resources, share industry progress, and highlight best practices to advance sustainable business in the outdoor industry. Today is the 50th anniversary of Earth Day, and the theme is climate change. Many of you are already aware of our newly launched Climate Action Corps. While we’ve slowed down some of our Climate Action Corps timelines and are taking time to check in, hear from you and meet you where you are, we will continue this important work, and it begins today. [/content] [/paniniblock] [/panini-column] [/panini-row] [panini-row layout=”row-full” ] [panini-column ] [paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”] [content name=”content” label=”Paragraph Content”] Watch this short video below for some reflections and good news, and below are links to some recommended Earth Day reading, listening and action. [/content] [/paniniblock] [paniniblock template=”basic/html” attribute-data=”name:template;type:text;label:Block”] [content name=”html” label=”Raw HTML”]

2:50

[/content] [/paniniblock] [/panini-column] [/panini-row] [panini-row layout=”row-full” row-width=”page-width”] [panini-column ] [paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”] [content name=”content” label=”Paragraph Content”]

CLIMATE

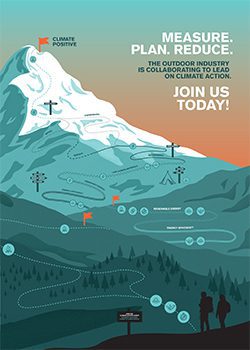

[/content] [/paniniblock] [paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”] [content name=”content” label=”Paragraph Content”] While climate risk may not feel as urgent and devastating as the current pandemic, it offers an important lesson. As this Yale Environment article describes, if we wait until we can see the impact, it is too late to stop it. We will still have a climate crisis when we get on the other side of coronavirus, and we all need a plan.

To date, more than 60 companies have committed to a plan: the Climate Action Corps. Over time they will measure their footprints, set targets, reduce emissions and share progress — and their journey starts today.

Today we celebrate these Founding Members, and we look to you and your company to lean in as this movement grows.

JOIN NOW ▸

[/content]

[/paniniblock]

[/panini-column]

[/panini-row]

[panini-row layout=”row-full” row-width=”page-width”]

[panini-column ]

[paniniblock template=”basic/html” attribute-data=”name:template;type:text;label:Block”]

[content name=”html” label=”Raw HTML”]

While climate risk may not feel as urgent and devastating as the current pandemic, it offers an important lesson. As this Yale Environment article describes, if we wait until we can see the impact, it is too late to stop it. We will still have a climate crisis when we get on the other side of coronavirus, and we all need a plan.

To date, more than 60 companies have committed to a plan: the Climate Action Corps. Over time they will measure their footprints, set targets, reduce emissions and share progress — and their journey starts today.

Today we celebrate these Founding Members, and we look to you and your company to lean in as this movement grows.

JOIN NOW ▸

[/content]

[/paniniblock]

[/panini-column]

[/panini-row]

[panini-row layout=”row-full” row-width=”page-width”]

[panini-column ]

[paniniblock template=”basic/html” attribute-data=”name:template;type:text;label:Block”]

[content name=”html” label=”Raw HTML”]

[/content] [/paniniblock] [/panini-column] [/panini-row] [panini-row layout=”row-full” row-width=”page-width”] [panini-column alignment=”align-right”] [paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”] [content name=”content” label=”Paragraph Content”]

CIRCULARITY

[/content] [/paniniblock] [paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”] [content name=”content” label=”Paragraph Content”] At a time of disrupted demand and a slowed economy, one opportunity remains promising for businesses: circularity. Borrowing from our Depression-era past, principles of reuse, repair and access-over-ownership offer new relevance and opportunities as consumption patterns and cultural norms shift in response to limited access to goods and spending caution given rising unemployment.

As this Green Biz article reminds us, if there’s any time for business to connect long-term economic value with fewer resources, it’s now. Of course, what opportunities are most relevant for your business will vary. Maybe it’s time to finally launch that subscription service, sell DIY repair kits, or incentivize product take-back to prep for a future used-gear program. Or it could be time to consider how to remanufacture that sitting warranty stock and past-season inventory. As with most things circular, the horizon of opportunity is endless.

Need a head start?

CHECK OUT OUR CIRCULARITY AND REPAIR RESOURCES▸

[/content]

[/paniniblock]

[/panini-column]

[/panini-row]

[panini-row layout=”row-full” row-width=”page-width”]

[panini-column ]

[paniniblock template=”basic/html” attribute-data=”name:template;type:text;label:Block”]

[content name=”html” label=”Raw HTML”]

At a time of disrupted demand and a slowed economy, one opportunity remains promising for businesses: circularity. Borrowing from our Depression-era past, principles of reuse, repair and access-over-ownership offer new relevance and opportunities as consumption patterns and cultural norms shift in response to limited access to goods and spending caution given rising unemployment.

As this Green Biz article reminds us, if there’s any time for business to connect long-term economic value with fewer resources, it’s now. Of course, what opportunities are most relevant for your business will vary. Maybe it’s time to finally launch that subscription service, sell DIY repair kits, or incentivize product take-back to prep for a future used-gear program. Or it could be time to consider how to remanufacture that sitting warranty stock and past-season inventory. As with most things circular, the horizon of opportunity is endless.

Need a head start?

CHECK OUT OUR CIRCULARITY AND REPAIR RESOURCES▸

[/content]

[/paniniblock]

[/panini-column]

[/panini-row]

[panini-row layout=”row-full” row-width=”page-width”]

[panini-column ]

[paniniblock template=”basic/html” attribute-data=”name:template;type:text;label:Block”]

[content name=”html” label=”Raw HTML”]

[/content] [/paniniblock] [/panini-column] [/panini-row] [panini-row layout=”row-full” row-width=”page-width”] [panini-column ] [paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”] [content name=”content” label=”Paragraph Content”]

CHEMICALS MANAGEMENT

[/content] [/paniniblock] [paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”] [content name=”content” label=”Paragraph Content”] With the rising need and use of hand sanitizers, disinfectants and anti-microbials comes a new wave of awareness about both what is in these essential products and what ensures their effectiveness – chemistry.

Chemistry has essential functions in modern life. As an industry, we recognize the critical role chemistry plays in our materials, manufacturing processes and final products. We’ve learned, as many are right now, that not all chemical inputs are alike. More than ever, it’s important to know what’s used to make products and their impact, fundamental knowledge built in to the Higg Index and the Climate Action Corps efforts. Whether it’s the ingredients in a Durable-Water-Repellent (DWR), or the solvents used to manufacture polyurethane (PU), we know that chemistry varies widely: in quality, consistency and its resulting impacts on the environment and human health.

As we explore ingredients for hand sanitizers and PPE materials and finishes today, let’s think about our work for tomorrow – understanding the chemistry used in our supply chain. Shared knowledge, data and resources enable our industry to select better chemical inputs and ensure how they’re used protects human health and the environment across global supply chains and at home.

Looking for guidance?

GETTING STARTED WITH CHEMICALS MANAGEMENT▸

CHEMICALS MANAGEMENT GUIDE AND TRAINING FOR MANUFACTURERS▸

[/content]

[/paniniblock]

[/panini-column]

[/panini-row]

[panini-row layout=”row-full” row-width=”page-width”]

[panini-column ]

[paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”]

[content name=”content” label=”Paragraph Content”]

Brought to you by the OIA Chemicals Management Community of Practice Steering Committee.

[/content]

[/paniniblock]

[/panini-column]

[/panini-row]

[panini-row layout=”row-full” row-width=”page-width”]

[panini-column ]

[paniniblock template=”basic/html” attribute-data=”name:template;type:text;label:Block”]

[content name=”html” label=”Raw HTML”]

With the rising need and use of hand sanitizers, disinfectants and anti-microbials comes a new wave of awareness about both what is in these essential products and what ensures their effectiveness – chemistry.

Chemistry has essential functions in modern life. As an industry, we recognize the critical role chemistry plays in our materials, manufacturing processes and final products. We’ve learned, as many are right now, that not all chemical inputs are alike. More than ever, it’s important to know what’s used to make products and their impact, fundamental knowledge built in to the Higg Index and the Climate Action Corps efforts. Whether it’s the ingredients in a Durable-Water-Repellent (DWR), or the solvents used to manufacture polyurethane (PU), we know that chemistry varies widely: in quality, consistency and its resulting impacts on the environment and human health.

As we explore ingredients for hand sanitizers and PPE materials and finishes today, let’s think about our work for tomorrow – understanding the chemistry used in our supply chain. Shared knowledge, data and resources enable our industry to select better chemical inputs and ensure how they’re used protects human health and the environment across global supply chains and at home.

Looking for guidance?

GETTING STARTED WITH CHEMICALS MANAGEMENT▸

CHEMICALS MANAGEMENT GUIDE AND TRAINING FOR MANUFACTURERS▸

[/content]

[/paniniblock]

[/panini-column]

[/panini-row]

[panini-row layout=”row-full” row-width=”page-width”]

[panini-column ]

[paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”]

[content name=”content” label=”Paragraph Content”]

Brought to you by the OIA Chemicals Management Community of Practice Steering Committee.

[/content]

[/paniniblock]

[/panini-column]

[/panini-row]

[panini-row layout=”row-full” row-width=”page-width”]

[panini-column ]

[paniniblock template=”basic/html” attribute-data=”name:template;type:text;label:Block”]

[content name=”html” label=”Raw HTML”]

[/content] [/paniniblock] [/panini-column] [/panini-row] [panini-row layout=”row-full” row-width=”page-width”] [panini-column ] [paniniblock template=”basic/paragraph” attribute-data=”name:template;type:text;label:Block”] [content name=”content” label=”Paragraph Content”]

READ, LISTEN AND TAKE ACTION

[/content] [/paniniblock] [/panini-column] [/panini-row] [panini-row layout=”row-full” row-width=”page-width”] [panini-column ] [paniniblock template=”basic/html” attribute-data=”name:template;type:text;label:Block”] [content name=”html” label=”Raw HTML”]- Article: Addressing Climate Change in a Post-Pandemic World

- Webinar: Using the Power of Data to Reduce Environmental Risk in Your Supply Chain

- Podcast: The Energy Gang—Will Pollution Pauses Have a Lasting Impact?

- Podcast: How to Solve Climate Change and Make Life More Awesome

- Vote: Join the Outdoor State and Pledge to Vote with POW!

- Podcast: Tara Brach on Meditation and Reflection

- Video: Freeride Skiing at Home