This Black History Month, we’re recognizing and celebrating Black leaders within the Outdoor Foundation’s Thrive Outside network. These individuals are not only shaping the landscape of outdoor leadership but are also reshaping our collective perception of who belongs in the outdoors. Follow along as we interview leaders from across the nationwide network and spotlight their voices throughout the month!

Akiima Price

Thrive Outside Washington D.C. Director

Why is Black leadership in the outdoors important?

Black leadership is essential in outdoor spaces because conservation goals have colonized the outdoor narrative. Our representation and diverse perspectives are essential in bringing back our stories into the narrative, both in the world and in Black communities. We have deep roots in agricultural heritage and innate connections to nature, and traditional knowledge and practices in the outdoors. At one point, skills such as hunting, fishing, foraging, sky reading, and herbalism were passed down through generations, providing sustenance and cultural significance. It is imperative that we model these practices to newer generations to restore them back into the values, habits, and traditions of black communities.

What brought you to the outdoors?

My father initially. He was raised in the South and loved to camp, fish, and bike. Quite naturally, I carried those values into my adulthood. However, the vision of Marta Cruz Kelly, Reginald “Flip” Hagood, and Destry Jarvis (all titans in the National Park Service in the 80’s and 90’s) called me into the movement. In 1991 they created the Career Conservation Development Program to expose women and people of color to careers in conservation. I was studying Communications at the University of Maryland Eastern Shore but was attracted to the opportunity of a summer job. Little did I know it would lead me to my life’s work.

Collective impact involves partners and stakeholders collaborating. What’s your role in Thrive Outside?

I direct the Thrive Outside DC initiative. I get to weave together a network of diverse, dynamic partners in Washington, DC, to address barriers to getting youth and families outdoors. The thing is, we have plenty of parks and green spaces within walking distance in DC; our access issues here are around safety and the awareness of the mental, physical, and social benefits outdoor spaces provide to economically stressed communities. I mainly do this work under The Anacostia Parks & Community Collaborative (APACC), a network of community leaders and organizations working together to make the Anacostia River and its park system the best possible resource for Ward 7 and 8 residents in the District of Columbia.

What’s your vision for the outdoors?

My ideal vision for the outdoors includes transforming parks into clinics and healing spaces, serving as cultural centers for family-based fellowship and healing for communities that have experienced trauma.

Chris Geden

The River City Foundation Director of Community Engagement, Thrive Outside St. Louis Director

Why is Black leadership in the outdoors important?

I really think representation matters, and it’s important for me to be an active participant in outdoor recreation if I’m going to be an advocate in this space. Also, the relationships that are made with our youth are often stronger as they learn new skills and conquer new challenges.

What brought you to the outdoors?

I grew up in a very rural white community, but I’ve always been involved with the outdoors—fishing, hunting, camping, and paddling. With every youth-serving position that I have worked in, one of the strategies that I used was nature-based programming. The opportunity to introduce youth to the outdoors in a sustainable manner is something that still excites me every single day.

Collective impact involves partners and stakeholders collaborating. What’s your role in Thrive Outside?

I am the Thrive Outside Program Manager and the Director of Community Engagement, so everything I do is based on collaborative relationships. Even more importantly, these are twenty-plus-year relationships with agencies, people, and communities. River City Outdoors seeks to positively impact the outdoor community by removing barriers for communities who are often underserved and not even included in conversations regarding their participation in the outdoors.

What’s your vision for the outdoors?

A totally inclusive environment in which all people are welcomed with open arms, and thoughts and experiences are shared. A total cultural shift on who is at the table as we talk about outdoor recreation.

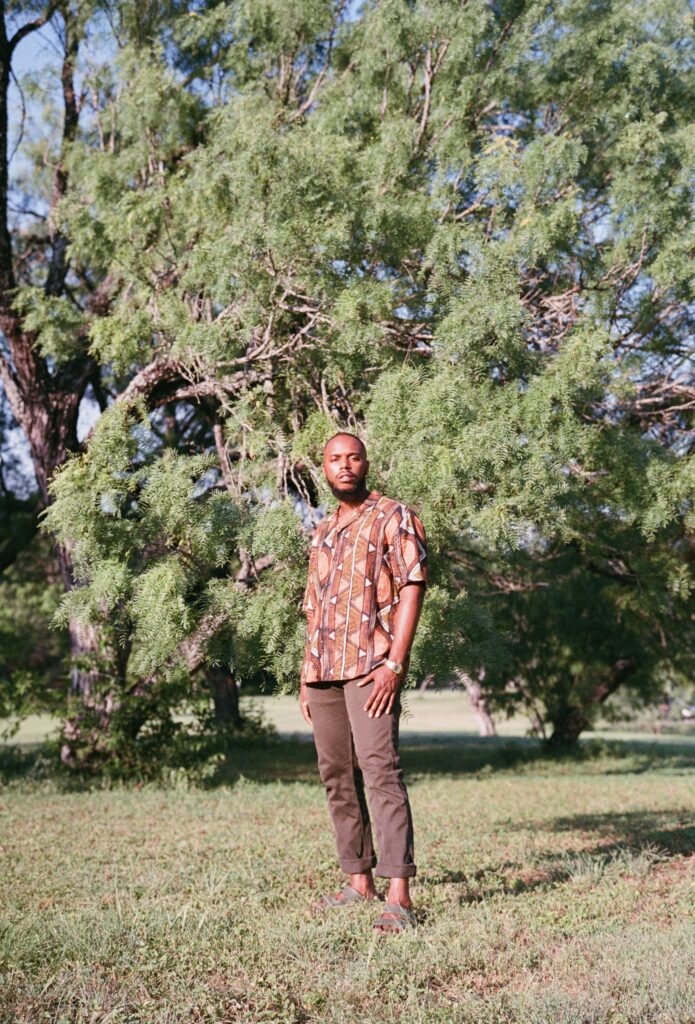

Jacob Fisher

Outdoor Foundation Development and Program Manager

Why is Black leadership in the outdoors important?

Let me start with these two truths:

- Being in nature is essential for your physical, mental, and spiritual health.

- Black folks have been historically excluded from the outdoors (often violently).

Black leadership is important because people from the African Diaspora have always been deeply connected to land. For survival, black people in the USA had to have an intimate connection to nature in order to endure the brutality of enslavement. This ranged from fishing, hunting, gardening, creating herbal medicines, and literally navigating to their freedom through knowledge of the stars and land. Thus, Black leadership merely reflects the truth that black people deserve the opportunity to offer our wisdom, guidance, and stories to the outdoor space.

What brought you to the outdoors?

Growing up in Tallahassee, Florida and Houston, TX, I was fishing, going to parks, playing tennis, and having family gatherings outdoors. As I began my mindfulness and yoga journey, my appreciation for nature was further ignited.

Prior to the Outdoor Foundation, I worked at an equine therapy and eco-mindfulness farm right outside of Austin, TX. In this space, I began intentionally connecting with the landscape and vastness within and all around you. Building my own capacity to resource myself and cultivate a nourishing and helpful relationship with nature.

I believe the land and all of its inhabitants are facilitators and wise teachers. The wisdom lies in the presence and awareness of the continuous lessons that nature uncovers. Developing a connection to nature has allowed me to move through the world with clarity, peace, and gratitude.

Collective impact involves partners and stakeholders collaborating. What’s your role in Thrive Outside?

I have the honor to be the Development and Program manager for the Outdoor Foundation. Therefore, I have the privilege to directly support our 13 Thrive Communities across the country. I serve as the Foundation’s lead contact for current and future Thrive Outside community partners.

Ultimately, I see my role as collective impact in action, and this ranges from:

- Lead the planning and execution of National Thrive Outside Days across all Thrive Outside Communities.

- Create, plan, and lead all efforts regarding the In-Person Convening for Thrive Communities.

- Facilitate and support the Outdoor Foundation’s Monthly Thrive Network meetings.

- Lead the planning and implementation of Quarterly Thrive Network Convening.

- Access and evaluate organizations, entities, and individuals that engage with Thrive Outside communities.

What’s your vision for the outdoors?

My vision is the integration of nature into everyone’s day to day life. Engaging with the benefits, joy, and liberation of nature is essential for being a human. Ideally, the outdoors will be a space that connects each of us to our internal world and to every being around us. Nature has the powerful ability to connect our inner change to social transformation. Hopefully, we can utilize the grounding and clarifying qualities of the outdoors to create a beautiful future where a sustainable and harmonious relationship with nature is actualized!

Dr. Na'Taki Osborne Jelks

West Atlanta Watershed Alliance Co-Founder/Executive Director, Atlanta Thrive Outside Director

Why is Black leadership in the outdoor space important?

Black leadership is critical in the outdoor space because time is overdue for Black people to fully connect to the outdoors and to all of the benefits and resources it brings to and provides our communities. Through Black leadership, we can help reclaim this lifeline that belongs to us and that should be positively experienced by all Black children, families, and communities. Especially in the United States, we’ve been disconnected through the legacies of slavery, lynching, and other horrors perpetrated against us in the outdoors. The lands and waters that our people have historically lived off, been stewards of, and possessed vast ecological knowledge about have many times been weaponized against us. To turn that trauma into healing by experiencing the outdoors in all of its beauty, splendor, freedom, opportunities for learning and exploration, and potential to inspire joy and connectedness to a sense of place—it’s our birthright.

What brought you into the outdoor space?

As a daughter of the South—born in Mississippi and living in Louisiana and Kentucky for parts of my adolescence—I’ve always had a connection to the outdoors. Whether it was spending time running around and playing with cousins on my paternal grandparents’ 95-acre farm in the Mississippi Delta, picking plums outside of my maternal Grandmother’s home in small town Central Mississippi, or even walking on the trail through the woods behind my Grandmother’s house to visit her sister nearby, my relationship with the outdoors has always seemed like a natural one. After those early experiences with family, I later joined Girl Scouts and most enjoyed going to Camp Judy Layne in Eastern Kentucky during summer breaks for tent camping and days filled with sunshine, the beauty of the natural landscape, and freedom in the outdoors. In contrast, I later witnessed Louisiana’s natural paradise being dotted with petrochemical plants and pollution that harmed the environment and human health. As an adult living on the Westside of Atlanta, Georgia amidst both beautiful urban forest spaces and near environmental hazards and stressors, all of my previous experiences have brought me into the outdoors, and my leadership is fueled by a passion to preserve, protect, and restore our natural resources for the well-being of my community and future generations.

Collective impact involves partners and stakeholders’ collaborating. What’s your role in Thrive and let me know about your organization?

The West Atlanta Watershed Alliance (WAWA) is the backbone organization of Thrive Outside Atlanta. WAWA has been a member of the Thrive Outside Atlanta Network since its formation in 2019, however we started out as one of the environmental education service providers—one of only two Black-led organizations in the group. As the COVID-19 Pandemic began to subside, WAWA took over the leadership reigns of the network from the Trust for Public Land and has been managing, cultivating, and deepening partnerships with youth environmental education and outdoor recreation providers as well as youth-serving organizations to engage youth from economically disadvantaged communities in nature and the outdoors through exploring both the Chattahoochee River and close-to-home Atlanta parks, trails, and greenspaces. For more than two decades, WAWA has pioneered efforts to advance environmental education, community engagement in watershed and greenspace protection, environmental stewardship, and environmental justice in Northwest and Southwest Atlanta neighborhoods. In part through this work, WAWA has been a leader in ensuring that access to nature and meaningful engagement in environmental education, environmental stewardship, and outdoor recreation are not factors of race, income, or geography, and our innovative, place-based, culturally relevant programs have introduced thousands to the creeks, streams, waterfalls, and abundant greenspaces in West Atlanta neighborhoods.

What is your vision of an ideal outdoor?

My vision of the ideal outdoors is one that is representative of the rich, diverse heritage and cultures of our country. It’s not exclusive to any one group, and it is accessible to all who will journey to know and experience it. It is one that honors the original inhabitants of the land as well as those who labored on the land by force or by choice to produce prosperity for the masses (that often didn’t include them). The ideal outdoors is one of unlimited connections and opportunities for kinship, stewardship, teaching and learning, exploration, healing, and joy. It’s a place where everyone can see themselves, where everyone can be themselves, where we all feel welcomed, and where we all are at home.

We all deserve to Thrive Outside

The Outdoor Foundation’s Thrive Outside Initiative is working to create a more inclusive and accessible outdoor experience for all. The initiative awards multi-year, capacity-building grants to diverse communities to build and strengthen networks that provide children and families with repeat and reinforcing experiences in the outdoors. The Thrive Outside Community Initiative helped to connect more than 40,000 youth and families in thirteen communities nationwide to the joy, wonder, and myriad benefits of the outdoors. Learn more about Thrive Outside here.